Carrying a small laser welding machine is much easier, which is the reason it’s the first choice for on-site welders.

Be it a DIY task, home repair, professional job, or anything you name, it can do the job with perfection.

For beginners, choosing the right small laser machine could be difficult. Because they have no idea of the small laser welding machine price and features.

In this article, we will go through some incredible small welding machines, the features you need to consider, and their prices for the best value.

What is Laser Welding?

In general, any kind of welding needs a source that can provide enough heat to melt metals so they can be fused together. In laser welding, this heat is produced using laser technology.

A laser beam is projected onto a small spot on the workpiece which melts and combines the metals to form a strong bond.

It can be used for welding a variety of different metals, non-metals, and in some cases, even dissimilar materials.

It is easily the fastest method of welding, giving the cleanest joints out of all the welding types. However, it requires a certain skill level to fully master this welding technique.

Major Components of Laser Welding Machine

A laser welding machine comprises different parts. Here I am going to discuss the most important of those components.

Laser Source

Lasers can be generated in a number of ways. The most commonly used materials for getting a laser beam are solid-state, liquid, gas, fiber, or semi-conductors.

When these materials are excited, the electrons absorb energy and move to a higher-energy orbit. These excited electrons return to their original energy orbits and emit the excess energy in the form of light particles called photons.

This continuous emission of photons forms a beam of light which we call a “laser”.

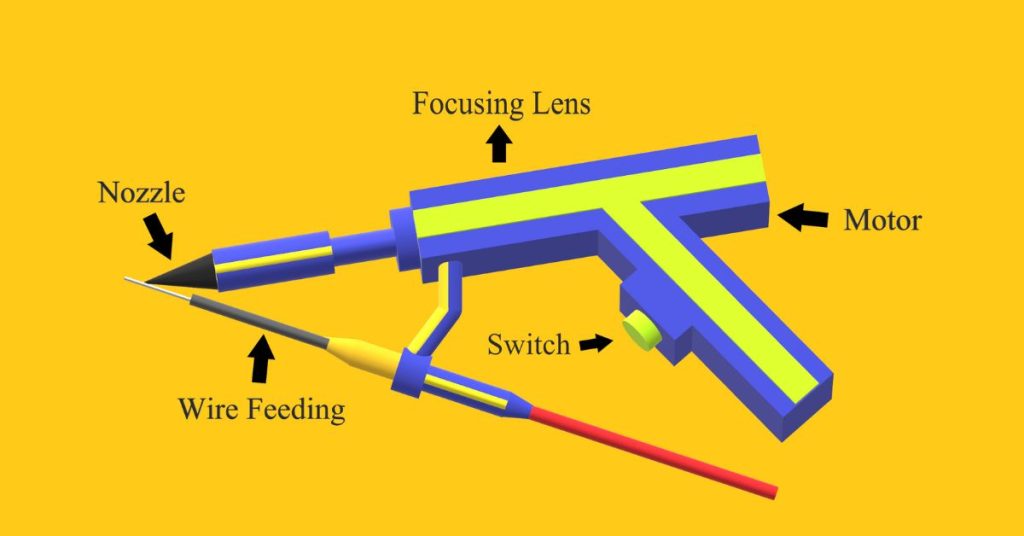

Welding Head

It is a handheld device that directs the laser beam onto the workpiece.

Most commonly used welding heads are hand-held.

One of the advantages of laser welding is that it can easily be automated. The welding head can be incorporated with some kind of robotic mechanism and you are good to go.

Cooling System

Since laser technology is used to generate heat, the material used to generate lasers can become extremely hot.

Therefore, one of the most important parts of laser welding is to keep the laser source at optimal temperature.

Two of the most common techniques used for this purpose are; water-cooled systems and air-cooled systems.

Both have their own pros and cons. Water-cooled system needs distilled water to create a cooling effect. Distilled water is preferred because normal water contains impurities and causes rusting.

Water cooling systems are generally quite robust allowing more professional tasks to be carried out which may require operating the machine for prolonged durations.

Whereas, the air cooling system requires less maintenance and allows an even more compact design of the machine.

If you are someone who require constant transportation of machines, an air-cooled system could be a better choice.

Things to Consider While Buying a Laser Welding Machine

Power Consumption

Small laser welding machines range from 1000 to 3000 Watts. The higher the power rating, the thicker the metals it can weld. And it also affects the small laser welding machine price.

Cooling System

As previously discussed, the cooling system is the second most important component after the laser source.

Therefore, selecting the correct type is really necessary. Choose a water-cooled machine if you plan to operate it for a long period of time. Otherwise, an air-cooled machine would be enough for most of the requirements.

4-in-1 Vs 2-in-1

These are two of the most common variants currently available in the market.

2-in-1 models come with just two functionalities; welding and welding seam cleaning.

Whereas, 4-in-1 is a multi-purpose machine targeted for more versatile consumers. It offers welding, cutting, rust removal, and seam cleaning, all housed in a single body.

Keep in mind your goal for purchasing a laser welding machine because the 4-in-1 variant could get a little pricey. For most of us, 2-in-1 machines would get our jobs done. The more functions it offers, the more will be the small laser welding machine price.

Ethernet or Internet Connection

There are a few brands that allow you to connect the welding machine to a computer using an ethernet cable or through the internet.

It allows you to get more data and precise control for the job.

Top Small Laser Welding Machine Price

Here I am going to compare the best currently available laser welding machines so it would be easier for you to decide which is best suitable for your requirements.

The pricing of these compact laser welding machines is between $6,000 to $11,000, depending on the features, functionality, and other factors.

1) WTTTools 2-in-1 Laser Welder

A 2000W laser welding machine suitable for DIY as well as heavy-duty tasks. It’s a 2-in-1 laser machine that can weld and clean seams like a pro. The best part is that you can switch to the desired mode just by pressing a button; no need to turn off the machine.

It is equipped with a lightweight and ergonomic welding machine that can offer 360-degree welding for optimal perfection.

Its water-cooling technology allows us to weld for a longer period of time.

The welding gun is provided with a warning reminder that turns red when the inner lens is near its operating limit indicating to pause so that the lens isn’t damaged.

If you are more of a hobbyist, there is a 1500 Watts variant also available. Whereas, if your usage requires more power you can opt for its 3000 Watts model.

2) Triumph 2000 Watts 4-in-1 Laser Welder

Instead of buying separate equipment for welding, cutting, rust removal, and welding seam cleaning, wouldn’t it be impressive to get just a single machine that can do all of this?

This model from Triumph just does this, while still being highly compact and easy to carry.

You simply need to switch the nozzle of the laser welding head and you are good to go from welding tasks to cutting jobs.

It also offers a pulse working mode which is really helpful when welding metals like aluminum or copper. Since these are highly shiny metals, using a laser in normal continuous mode results in a loss of energy as heat because of the reflection after striking the metals’ surface.

3) WTTTools Air Cooled Welder

Don’t be fooled by its small size and just 1200 Watts power requirement. A 2-in-1 laser machine that comes with an air cooled system.

It is an equipment which is a must-have for any DIY enthusiast. From its price to its size to its power, everything makes it perfect to be easily carried anywhere. Still, it’s versatile enough to perform any kind of job.

Due to its air cooling, it’s easy to maintain as compared to water-cooled welders.

It comes with an even lighter handheld welder which is just 1.4 lbs. It would be nearly impossible to get it any lighter with all the professional features.

The most amazing feature is that it comes bundled with an impressive 7” touch screen where we can easily select different modes that have preset values of all the parameters. Just select the mode depending on the material to be welded and its thickness, eliminating the need to manually set any of the parameters.

All these features make it a no-brainer choice for beginners who are new to laser welding.

4) Hero 1500 Watts Air Cooled Welder

Hero is one of the few brands offering 915nm laser technology.

When coupled with this latest energy-saving technology, the air-cooled system can carry out any heavy-duty job with an estimated electricity saving of 50% as compared to water-cooled laser welding machines.

This model also has the ability to connect to the internet enabling real-time monitoring and storage of data. This could be helpful to improve efficiency and overall productivity.

Although its 1500 Watts power consumption is on the lower side for a small laser welder, if you feel that an even smaller welder would be suitable for you, there is a 1000 Watts version also available including all the same features.

Final Words

Small laser welding machines are quite handy and people like to use them for on-site jobs and DIY. We have explained how you can select a small laser welding machines by considering some important factors. The small laser welding machine price ranges from $5,000 to $11,000 on the market. You have to choose according to your requirements and applications. Check out the laser machines we have shared to make your selection easier.