A Detailed Guide on Chopped Welding Hoods

For every welder, a welding hood is a must-have. It is essential to ensure the safety of the welder and allow him to work with perfection and without any hassle.

But for different purposes, there are different welding hoods. There is a difference in their material and design. One of them is a Chopped Welding Hood.

In this article, I will discuss what Chopped Welding Hoods are and how they are made. I will share a detailed guide and review to teach everything about them.

Let’s start the discussion.

What Are Chopped Welding Hoods?

Beginners and sometimes even experts do not know much about chopped welding hoods. They are amazed after listening to the name of the welding. It is because these are used especially in the oil and gas industry for welding pipelines.

Chopped welding hoods are modified hoods that have a chopped top, bottom, or both. A simple pipeliner welding hood is cut from the top and the bottom, which is the reason behind the unique name of the welding hood.

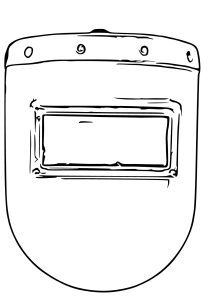

Design of a Pipeliner welding hood

A regular pipeline welding hood is curved from the top. This curvature is cut or chopped, and another material, usually leather, is used to create a plain perpendicular surface to the curvature of the hood. The leather surface fits perfectly well on the head of the welder.

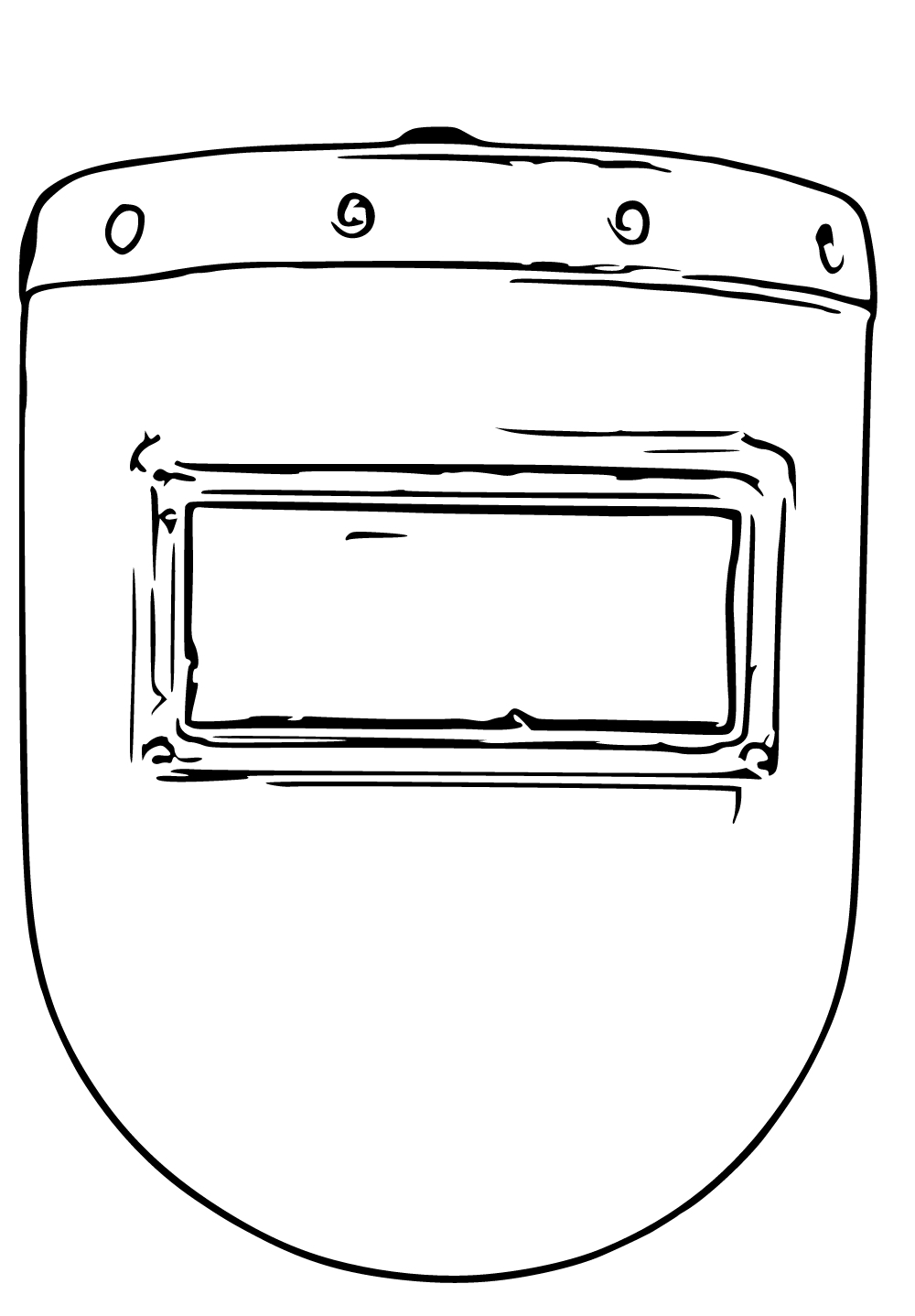

The design of a chopped welding hood

What are the Benefits of Chopped Welding Hoods?

You might be thinking why there is any need to modify welding hoods and chop their top or bottom. But this modification has some exceptional benefits.

Like all welding hoods, chopped welding hoods also protect the face of the welder from extreme light, sparks, small particles, and heat. These do the job with perfection. Other than that, the welding hoods have the following benefits.

When a welder welds a material, the light comes from the rear top of the hood. It could be sunlight, artificial light in the working area, or the reflected light from welding. It creates a reflection on the welding lens and blurs the vision. Therefore, the welder faces difficulties and cannot do his job with perfection.

The benefit of the top chopped surface is that it blocks the light coming from the rear top. The leather fits perfectly well on the head and does not allow light to enter the welding hood. Therefore, the welder can see the working area clearly and is not disturbed by the lighting in the area. It allows the welder to work in a daylight and bright environment.

The bottom of a chopped welding hood is also cut. It is done to prevent scratches on the chest of the welder. After cutting the bottom, welders feel more comfortable. But this bottom cut depends on the welder. According to the face, the welders can select slight-cut, medium, or no-cut welding hoods.

How Do You Cut a Welding Hood

If you want to turn a pipeliner welding hood into a chopped welding hood, you need to use a sharp tool to cut the hood.

Usually, manufacturers or modifiers use a jigsaw to cut the hood in the desired shape. But the selection of the blade also plays an important role. It should be selected according to the material of the hood.

If you want to make the top cut, leave a couple of inches above the lens. It can be adjusted according to the welder, but it is usually 1.5-2 inches.

The bottom cut is adjusted according to the welder. It can be a medium or slim cut.

How Are Chopped Welding Hoods Made?

A standard Pipeliner welding is transformed into a chopped welding hood after some modifications.

First of all, a piece of leather is cut in a D-shape according to the size of the welding hood. It is soaked in water and stretched on a piece of wood that has the ideal design. After drying, the leather attains the required shape.

D-shape leather cutting for chopped welding hood

In the meantime, the pipeliner welding hood is cut from the top. By using a jigsaw, the hood is cut from the top after leaving around a couple of inches from the lens. It is a straight cut on which the leather will be fitted. According to the welder, the bottom is also cut using a jigsaw.

Now, several holes are made in the hood to fix the leather top. Similar holes are also made on leather. Glue is applied to the leather, and it is fixed using suitable rivets.

The lens, headband, and fasteners are fixed on the hood, and now, it is ready to be used.

You can make chopped welding hoods on your own if you know how to use the required tools, but be careful. Otherwise, you can order from a reliable modifier.

Difference Between Chopped Welding Hoods, Sugar Scoop Welding Hoods, and Pipeliner Welding Hoods

People often get confused due to these names, and sometimes, these are also used interchangeably.

Pipeliner welding hoods are used for pipelines. It is a registered trademark, and these have a standard shape and design.

Sugar Scoop Welding Hoods is the common or generic name for Pipeliner welding hoods. These are the same.

Chopped welding hoods are the modified and chopped versions of Pipeliner/Sugar Scoop welding hoods.

Now, you might have a clear idea of these welding hood names.

Brief Chopped Welding Hoods Review

Chopped welding hoods are great for bright environments. They prevent light from the back of the hood and help in perfect welding. With that being said, you can use them in sunlight or any bright working area.

Many welders love using a chopped welding hood. It is lighter than the regular one because some of its portion is chopped. The leather is quite comfortable, and some welders also like to have a leather bottom to cover their neck and a wider area.

Chipped welding hoods can be customized. There is a wide variety of leather patterns that welders can choose from. It has a very compact design and can easily fit those spaces where standard helmets cannot. They are also equipped with a gold welding lens to ensure high visibility.

Due to the additional benefits of chopped welding hoods, welders like to have them for their work. It is a worthy investment that pays off.

There are multiple manufacturers and modifiers that offer chopped welding hoods. But due to customization, they take time to deliver the product.