How to Make a Welding Skid—Everything Explained

For a welding job, you need to move the welding machine and other required tools and equipment to the place where you want to weld. The transportation is quite simple if you have a small welding machine that is used for common welding tasks at homes and offices. Such types of machines can be easily transported in simple cars because they are small, lightweight, and portable.

But some welding machines are bulky. For instance, the welding machines used for pipeline welding are massive. They are heavy and large, so they cannot be transported easily. You need a special and dedicated vehicle or truck that can move the welding machine and other necessary tools and equipment. And that is where a welding skid comes into play. It assists in transporting and moving welding machines from one place to another without any hassle.

In this blog post, I’m going to discuss all about welding skids in detail. I will discuss what a welding skid is and how you can make a customized welding skid of your choice. I will share the detailed steps along with some graphical representations to make everything easier. I will also discuss important things to consider, welding skid ideas, and whether you should buy a ready-made welding skid or not.

Let’s begin!

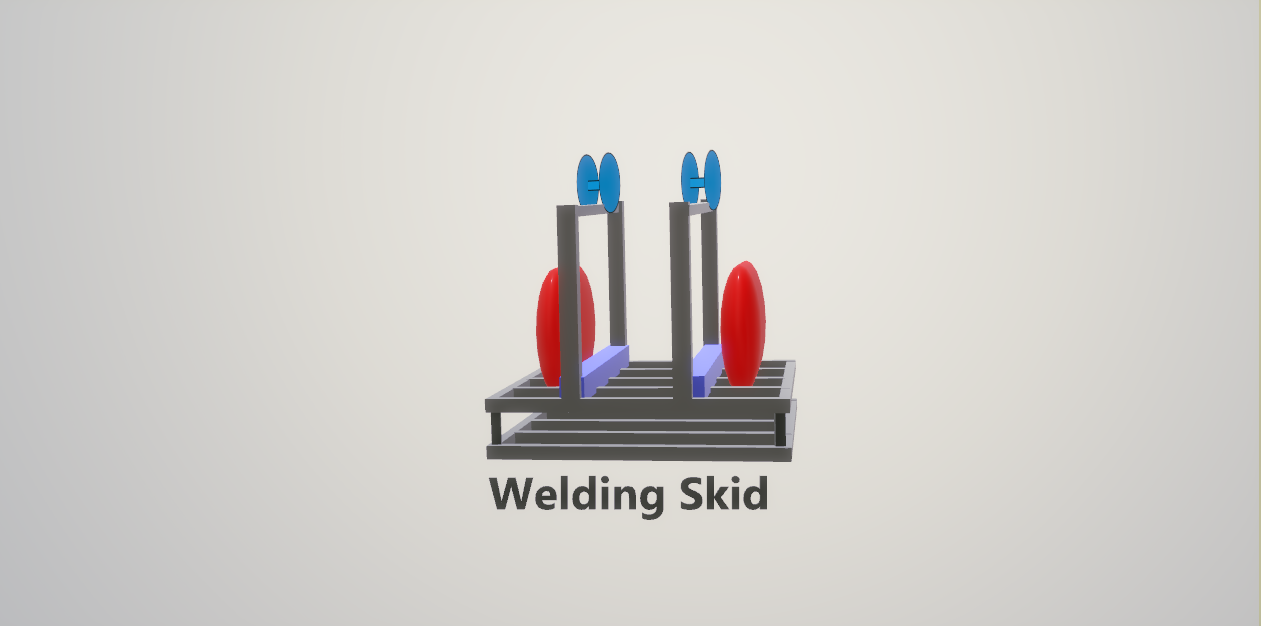

What is a Welding Skid?

You cannot place large welding machines directly on a vehicle or truck. You need a frame to hold the welding machine. This frame or base is called a welding skid.

A welding skid is a simple welding machine platform. The machine is fixed to it, and there are dedicated spaces for other accessories, such as propane tanks, gauges, reels, tools, etc. Due to the welding skid, everything remains secured in its place during the movement.

A welding skid makes the transportation of the welding machine, required tools, and accessories a lot easier. It turns the vehicle into a running welding shop.

The best part is that the welding skid can be removed from the truck whenever needed. Using a forklift, the welding skid can be removed or installed. For pipeline welders, it is a must-have.

However, some welders also create a customized welding skid that is permanently fitted at the back of the truck. Anything is possible according to the needs and ease of the welder.

Materials and Tools You Need to Make a Welding Skid

You need metal pieces, pipes, and sheets for creating a welding skid of your choice. The selection of material depends on your budget and preference. If you want to save money, it is possible to get scrap iron pieces and then weld them together. It will save you a ton of money.

You can also choose aluminum extrusions, aluminum mill plates, carbon steel, or whatever you want. First, look at your budget and see which materials are suitable for your jobs. Once you have the sheets and bars, you can create a structure on which your welding machine will rest.

Other than these things, you need cable reels, cylinder holders, gauges, latches, nuts & bolts, etc. These will be welded with the frame. You will also need paint for the frame because it will keep the metal safe from rusting and corrosion.

The most important tool you need is the welding machine to weld the pieces together. Then, you need a drill machine, sander, grinder, clamps, speed square, metal files, hammer, and the other common tools and accessories required for welding.

Welding involves various hazards, so make sure you take all safety measures. There should be a fire extinguisher to deal with accidents. Use a proper welding helmet/chopped welding hood, welding arm guard, gloves, and safety glasses.

How to Make a Welding Skid

Welders can make their own welding skid, and it is the best option. They can customize everything according to their needs and make a perfect welding skid of their liking.

Making a welding skid is not that difficult. It is pretty simple and only requires some basic welding skills.

First, you need to take the measurements of the vehicle and the welding machine. It gives you a clear idea of the size of the welding skid. You need to make a rough diagram of the welding skid before you start. Take the measurements and adjust the design according to your needs.

Once your design is ready, you can start making the welding skid.

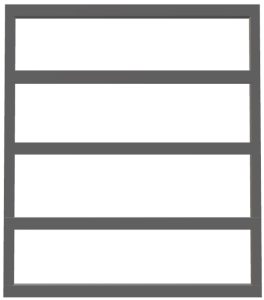

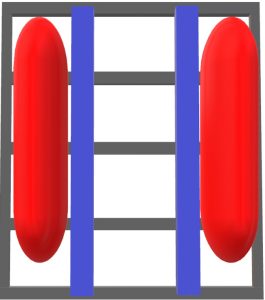

Step 1: You should start with the base frame of the skid. It should be according to the size of the truck. Create a simple rectangle using the bars, and make sure to measure everything correctly.

Step 2: To make the frame stronger, it is necessary to add a few bars in between.

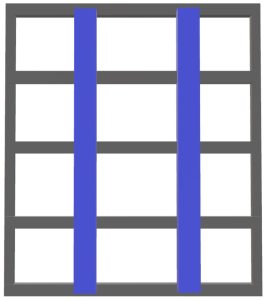

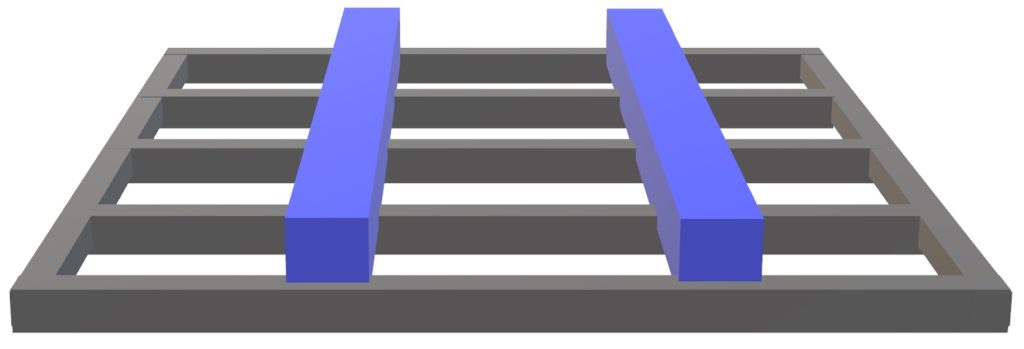

Step 3: Once the frame is ready, it is time to create a dedicated space for the welding machine. Keep in mind that the welding machine should be higher than the truck bottom. It helps in cleaning and maintenance.

Step 4: The base frame is ready. You can now make dedicated spaces for cylinders, reels, and other things you want.

Step 5: The welding skid is almost ready. Now, you can customize it according to your needs. For instance, you can make a frame at the sides as well. There can be a toolbox, cord box, cord hangers, etc. You can tweak things according to your needs and comfort. Moreover, you can use metal sheets to cover the holes and boxes for tools and accessories.

Things to Consider While Making a Welder Skid

1) Material

A welding skid holds the heavy welding machine and other accessories. It should be strong and sturdy enough. Secondly, it is placed on the truck by using a forklift or any suitable machine, so the frame of the skid should be durable.

You have to choose the material, thickness, and other things carefully. Thin aluminum or anything like that won’t last for a long time.

2) Measurements

Everything relies on the measurements you take. Make sure to pay attention while measuring the size of the truck and welding machine carefully.

After making the initial frame, try to place it in the truck to see how it fits. You will get an idea of the mistakes and issues if there are any. It is better to do it initially rather than regretting it at the end.

3) Equipment and Accessories

You should have a welding skid layout before you start. There should be dedicated places for equipment and accessories. Take the measurements of the cylinder and other things you want to add to the welding skid. We have explained how you can start with the frame and then adjust other things one by one.

Welding Skid Ideas

Here are some welding skid ideas you can consider according to your vehicle.

1) Simple Base Frame

It is a simple and portable welding skid idea. You just have to create a base frame for the welding machine and other things. Just make the frame as you have demonstrated in Step 1 and Step 2.

Then place the welding skid and other things on the machine. It is the simplest design, and the most affordable one. It is good for small trucks and small welding machines.

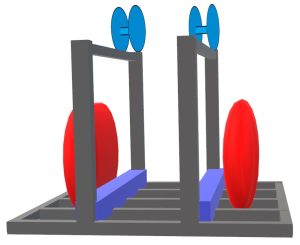

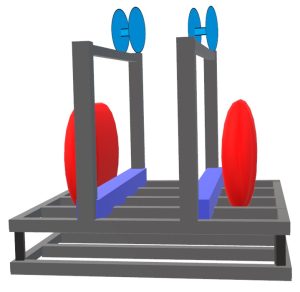

2) Center Welding Machine

This idea is good for large trucks that have enough space to have a welding machine in the middle and some space left on the sides. This is the same idea that we have demonstrated in the how-to steps. It is the most common welding skid design.

3) Welding Machine on the Side

If your truck is a bit small, you can place the welding skid on any of the sides and leave the other side for cylinders. It is also good if you want to have more space on one side for accessories.

4) The Storage Drawer

Some welders love to have a hidden drawer to keep their tools and equipment. For this idea, you have to keep the welding skid a bit high and make a simple drawer at the bottom. You will be able to use the maximum space of your truck.

First, make the frame, and create a drawer under it. Check out the image below. It will require more effort, but it is worth it.

Should You Go with Ready-Made Welding Skids?

You will find various manufacturers that can ship you a ready-made welding skid, but you have to compromise on a lot of things.

Firstly, you need to search for the right welding skid according to the size of your truck or vehicle. Keep in mind that readymade welding skids are made for specific welding machines, so you need to consider that in mind. The machines that can fit in the size are usually mentioned in the specifications. Sometimes, it is quite hard to find the right skid according to the machine because manufacturers usually make the ready-made versions of the popular machines available.

Then, you need to pay attention to the construction material, the design, things you can place in the skid, etc. You might not have a toolbox, a separate cord box, and various other things you might want to have on the welding machine.

My concern is that if you are paying a hefty amount for a ready-made welding skid, why not get a custom-made welding skid of your choice? In a customized skid, you can select the right material and its thickness. You can adjust the position of the welding machine, cylinders, toolboxes, cords, reels, and everything. You get whatever you like, and the most important thing is that it fits in the truck perfectly.

If you can make a welding skid on your own, it will be great. It will save you money and offer complete satisfaction. But if not, you can hire a professional who can make a customized welding skid for you.

You can go with a ready-made welding skid if the desired design, size, and machine compatibility are available. Check some popular online stores and get quotes for them.