Welder Bed—How to Make One?

For on-site welding tasks, welders, especially pipeline welders, have a truck to carry the welding machine and other tools and equipment. You cannot put the machine and other things directly on the truck; there should be a dedicated place to secure everything.

There are two ways to transport welding machines and equipment through a vehicle truck. One is the welding skid, which we discussed a few days ago. The other option is a welding bed.

In this blog post, we will discuss welding beds in detail. We will explain the step-by-step procedure to make a customized welding bed and share tips and bits of advice.

Let’s begin!

What is a Welding Bed?

A welding bed is a permanent fixture on the vehicle or truck that is made for carrying welding machines and other accessories. Unlike a welding skid, the back of the vehicle is removed and a welding bed is made. It completely changes the shape and construction of the vehicle, or you can say that the vehicle is modified.

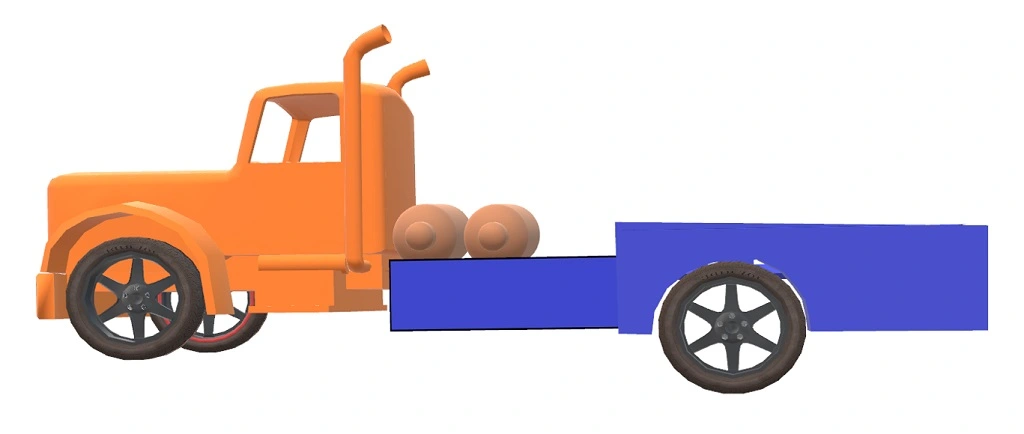

It makes welding pipelines and doing outdoor/on-site welding tasks a lot easier. The welding machine, cylinders, toolbox, reels, and cords can be fixed at the back. There are dedicated spaces for everything. The truck is turned into a permanent running welding shop.

A welding bed can be made or adjusted according to the needs of the welder. The machine can be placed in the center or the side. The gas cylinders and toolboxes can be placed anywhere. Thus, a welder bed can be made according to the liking of the welder. There is no hard and fast design.

Welding Truck Beds vs Welding Skids

Welding skids can be removed and installed on the truck through a forklift or a lifting machine. The truck is not modified in any way.

It is just a simple frame that holds the welding machine and other things in place during the trip. It is good for those who do not do frequent outdoor jobs or who do not want to modify their vehicle.

On the other hand, welding truck beds are installed at the back of the vehicle after removing the rear end that was installed by the manufacturer. So, these completely change the vehicle. But they are ideal for pipeline welders and those who have a dedicated vehicle for on-site welding jobs.

Materials Required for Making a Welder Bed

For making a standard welding skid with the required accessories, there are some essential materials and things. Before you start, it is important to know what you need and get a general idea of the expenditure.

Metal Tubes

The most important material for the construction of a welding bed is metal tubes. These create the whole structure and make the welder bed strong and sturdy.

It depends on your choice of what kind of metal tube you want to use. It could be iron, stainless steel, or anything you like. It depends on the budget. Secondly, the size of the metal tubes could be 4” x 2” or 2” x 2”. You can use both rectangle and square tubes to get the desired shape and strength.

Metal Sheets

After making the frame, metal sheets are placed on them to create a bed. These metal sheets are usually stainless steel. The thickness of the sheet depends on your choice, but usually 1/8” thick sheets are used.

Stainless steel is a good choice because it looks good and lasts for a long time. There is no need to worry about rusting and painting. If you want to go cheaper, you may look for other options or scrap items.

Pipes

Some metal pipes may be needed to make sections on the welding bed. They hold various accessories and offer support. They are also helpful for creating holders for welding reels and cords. According to your design, you can buy pipes.

Locks

Locks are required for the toolbox. You may need one or two locks to keep all tools and accessories safe.

Things to Consider While Making a Welder Bed

Proper Planning and Designing

Before you start making a welder bed, you should confirm the design. You need a complete plan to make a perfect welding bed.

Make a design on a piece of paper, or if you can make it on software, it will be better. Once the design is ready, you can take steps accordingly. It prevents errors and mistakes.

Accurate Measurements

The accuracy of measurements is very important. Otherwise, the design of the bed or its strength can be affected. Be attentive while taking the measurements. You are going to modify the vehicle, so everything should be inch-perfect.

How to Make a Welding Bed?

Making a welding bed is not easy. It requires a lot of time, dedication, skills, and concentration. You have to follow each step carefully. It may take several days to make and cost around $1,000 to $10,000, depending on the size and other features. You may have to speed a week or so in making a perfect welder bed of your choice.

Let’s see how you can make a good welding bed.

Step 1: The first step is to remove the rear end of the vehicle or truck. You need to disassemble that to make a new frame for the welding bed. Disassemble it carefully and if you don’t know how to do that, check some videos on the internet or get help from a mechanic.

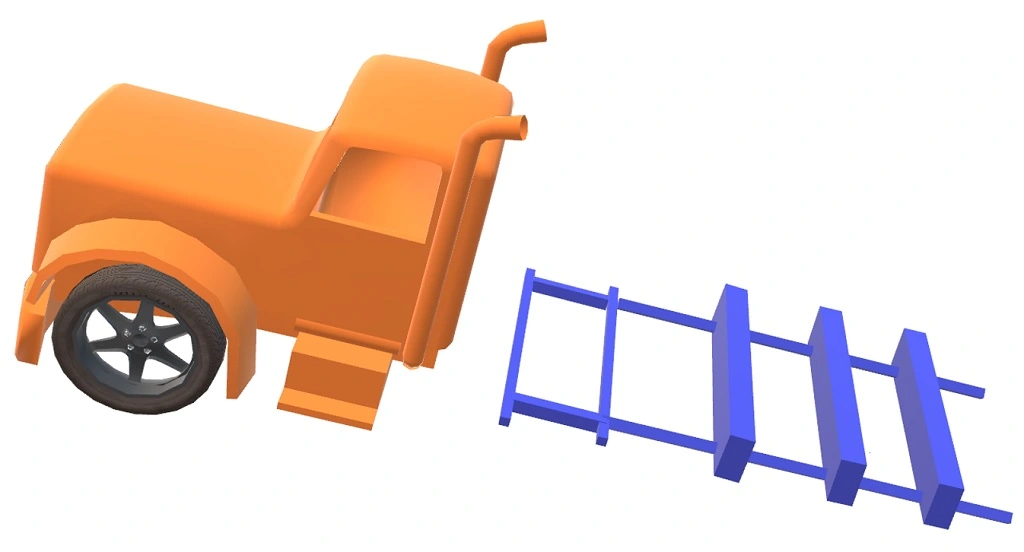

Step 2: Now, we need to start making the main frame of the welding bed. For this, you will need rectangular metal tubes/pipes. You may also need square tubes as well. It depends on what you prefer on your welding bed. Ideally, 2” square tubes and 2” x 4” rectangle tubes are suitable.

We arranged the tubes as shown in the diagram and welded all of them together. It is a strong frame, and you can also amend it as you like. It is just to give you an idea of how to make the main frame.

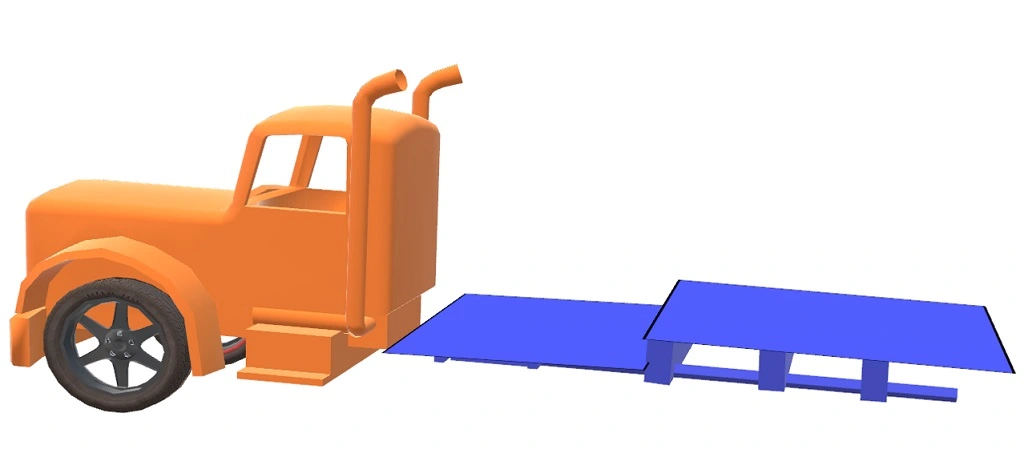

Step 3: The main frame is ready. It is time to weld sheets over the frame and give this welding bed a nice platform. You need to weld the sheets at the front and the back. Take the measurements and cut the required size.

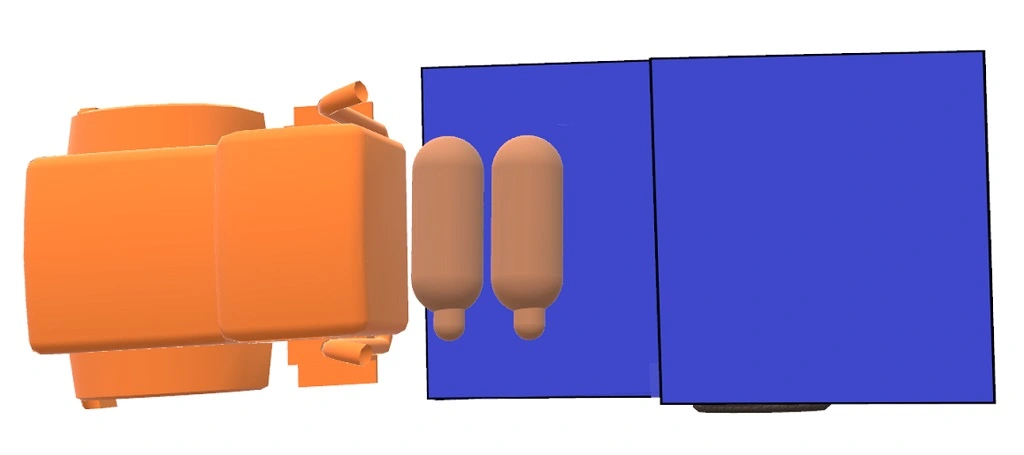

Step 4: It is time to make dedicated spaces for cylinders. These are quite important. We are placing two cylinders here just to show it can be done. You can have more cylinders for acetylene and oxygen.

Step 5: After that, you need to weld metal sheets on the sides and the back. It is one of the most difficult steps. You have to make an arc on the sheet to make space for the tires. Do it carefully and make sure to leave enough space between the sheet and the tire.

Step 6: There should be one or two toolboxes to keep all the tools in one place. These are quite simple to make, and you can place them wherever you want.

These steps demonstrate easy steps to make a welder bed. They just give an idea, so you can modify the design and adjust things according to your needs.

Can You Get Ready-made Welding Beds?

The simple answer is No. You cannot get read-made welding beds because these require modification in the vehicle. The only option is to get a custom-made welding bed, and the service provider will take your vehicle for a few days and make a welding bed of your choice.

You can get the bed customized as you like. But keep in mind that it will be expensive because of the labor cost. It is better to use your welding skills and build a welding bed on your own. It is a bit difficult, but you can do it with proper planning.

We have already discussed the detailed steps to make a welding bed. You can follow those steps and create a welding bed without any hassle. It will save you money, and you will be able to arrange things according to your liking.