The Best Stick Welding Stinger—Top 5 List

A welding stinger plays an important part in the overall quality of the weld. Therefore, welders look for the best stick welding stingers to achieve perfection.

It is also one of the most frequently used equipment because welders hold it all the time during welding. It has to be sturdy, ergonomic, and of optimal quality.

In this article, we will discuss what makes the best welding stinger and what you need to look for while selecting it. We will also share some of the best welding stingers along with their features, pros, and cons.

What is a Stinger in Welding?

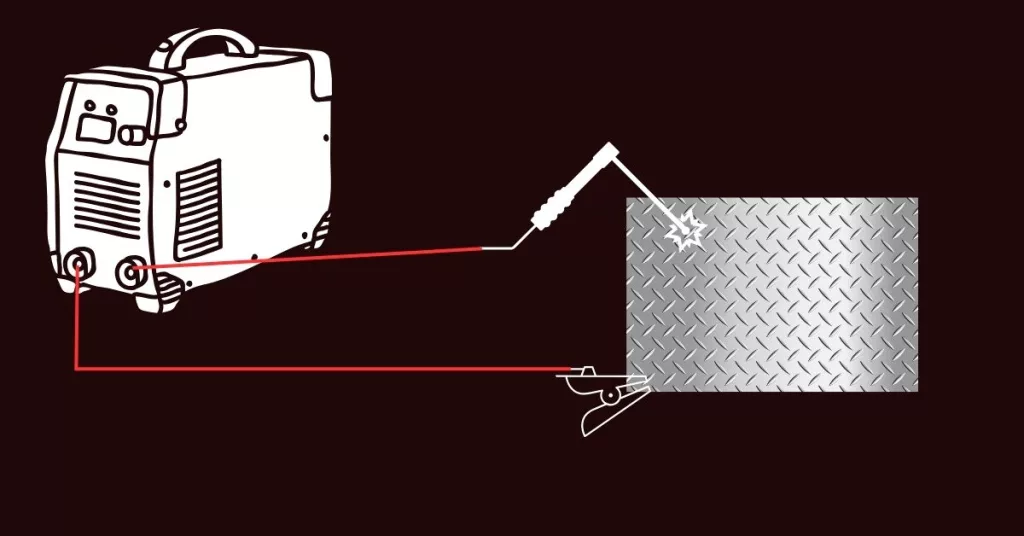

A welding stinger holds the welding electrode during the welding process, which is why it is also called a welding holder.

It not only holds the electrode but also completes the circuit to create an electric arc through a short circuit. The arc produces enough heat to melt the metal pieces and weld them.

The welding stinger is actually the positive end or pole. While the metal itself is connected to the negative clamp, it becomes negative.

When the welder touches the metal through the electrode, it is just like short-circuiting the positive and negative ends, which results in an arc.

The stinger also has insulation, which keeps the welder safe. It prevents heat and electric current from harming the person.

Can You Change a Welding Stinger of Any Welding Machine?

Welding stingers can be changed. You need to buy a suitable stinger according to the machine from the aftermarket.

Some welding machines sell stingers as spare parts, but if you do not find one, you can go with third-party reliable stingers as a replacement.

It is quite easy to change the welding stinger. You just need to remove the back insulation and remove the cable. The same cable can be used with the new welding stinger.

How to Choose the Best Welding Stinger

Before you buy a welding stinger, check these important factors that must be considered. These will help you select the best welding holder without any hassle.

Type of Welding Stinger

Selecting the right type of welding stinger is the first step. There are two basic types: Clamp Style and Screw Type.

Both types of welding stingers are great, and it depends on the preference of the welder. Usually, people go with clamp-style stingers. It is the most widely used option.

The screw-type welding stinger holds the electrode tightly, but some people find it difficult to screw and unscrew it again and again. However, this type of welding stinger allows you to bend the electrode to any angle, which makes it suitable for any purpose and confined spaces.

Ampere Rating

Ampere rating is the most important specification to look at. It gives you an idea of where you can use the stinger.

The lowest ampere ratings are 100-200 amperes. These welding stinger holders are suitable for light-duty welding. They can weld thin and light materials.

Most people usually go with 200-300 ampere welding stingers. They are ideal for commercial purposes and can do a variety of jobs.

For heavy-duty industrial applications, such as pipeline welding, welders go with 300-500 ampere welding stingers.

Jaws

The jaws of a welding stinger hold the electrode. If they are not durable, the stinger won’t work for a long time. Check the material from which the jaws are made. Copper and copper alloys are excellent options because they are not only durable but also offer good conductivity.

Design

The design of a welding stinger is often overlooked. However, it plays an important role. When welders work for a long time, they feel pain and strain in their hands. So, the design should be ergonomic to offer longer working hours without any discomfort.

Cable Connection Size

Last but not least is the cable connection size. All welding stingers require a specific cable size. You can check this specification to match with your existing cable.

Best Welding Stingers

We have hand-picked some of the excellent welding stingers that are a bang for your buck. We will discuss their pros, cons, and other details for quick comparison.

Tweco Ergo Electrode Holder (200 Amp, Clamp Style)

An experienced welder would love to have a Tweco stinger. It is one of the most reliable welding stinger brands on the market.

The Ergo electrode holder is an incredible piece. Its design is unique, which is not only extra comfortable and ergonomic but also appealing.

Its jaws are perfect, and the clamp is also tight enough. It will offer optimal conductivity and good results in all welding jobs.

Lincoln Electric Industrial Electrode Holder (200, 250, 300, & 350 Amps, Clamp Style)

Lincoln Electric is known for the aftermarket parts related to welding, whether it be auto-darkening welding lenses, safety gears, or electrode holders.

There are four variants of the electrode holder available, including 200-Amp, 250-Amp, 300-Amp, and 350-Amp. The built quality is excellent and up to the mark.

The stingers are made to offer a comfortable experience to the welders. It is lightweight, and the design is ergonomic. Secondly, it is compact enough to fit even confined spaces.

The jaws are made of copper alloy, which offers maximum conductivity and excellent welds. You can use it for industrial as well as other purposes.

But keep in mind that all variants have different maximum cable sizes. The 200-Amp and 250-Amp variants have 1/0 max size, while the 300-Amp has 2/0, and 350-Amp has 3/0.

Hobart Welding Holder Electrode (400 Amp, Screw Type)

This is a screw-type welding stinger suitable for industrial applications and pipeline welding. It is a great choice for those who do not like the clamp of the normal holders.

It has a better ergonomic design for long welds. You can bend the electrode in any direction for better grip and weld. Changing the electrode is also easy; you need to unscrew it a bit.

The amp rating is 400. It is suitable for rods up to 5/16” and an ideal option for 1/16” rods. It offers excellent insulation and performance. But keep in mind that everyone is not comfortable with using this kind of welding stinger.

The only issue with this type of welding stinger is that the hole and rod tightening mechanism have some limitations. You might face an issue in gripping some electrodes.

SÜA Stick Welding Electrode Holder (300 and 500 Amp, Clamp Style)

It is a sturdy and durable clamp-style stick welding holder. It is definitely worth every penny you spend on it. The body is made of tough nylon, which lasts for a long time.

It is a good option for high amperage. You can get the 300-Amp or 500-Amp holder at a suitable price. It works well, and the high-strength spring holds the electrode tightly.

The jaws and the connector ensure excellent conductivity. It takes cable size up to 2/0 for both the 300-Amp and 500-Amp variants.

Tweco Tong Electrode Holder (300 Amp, Clamp Style)

This is another Tweco electrode holder rated 300-Amp. It holds the electrode perfectly in any position because of its 6-jaw patterns. And the copper alloy ensures excellent conductivity.

You can use any electrode up to 7/32”, which makes it a good option for welders. The insulation on the stinger is up to the mark and of high quality.

There is also a spring protection system for the cable to prevent breakage. It works perfectly well with cables up to 2/0.

For regular users, it is a durable choice. Its built quality is amazing, which ensures its long life.